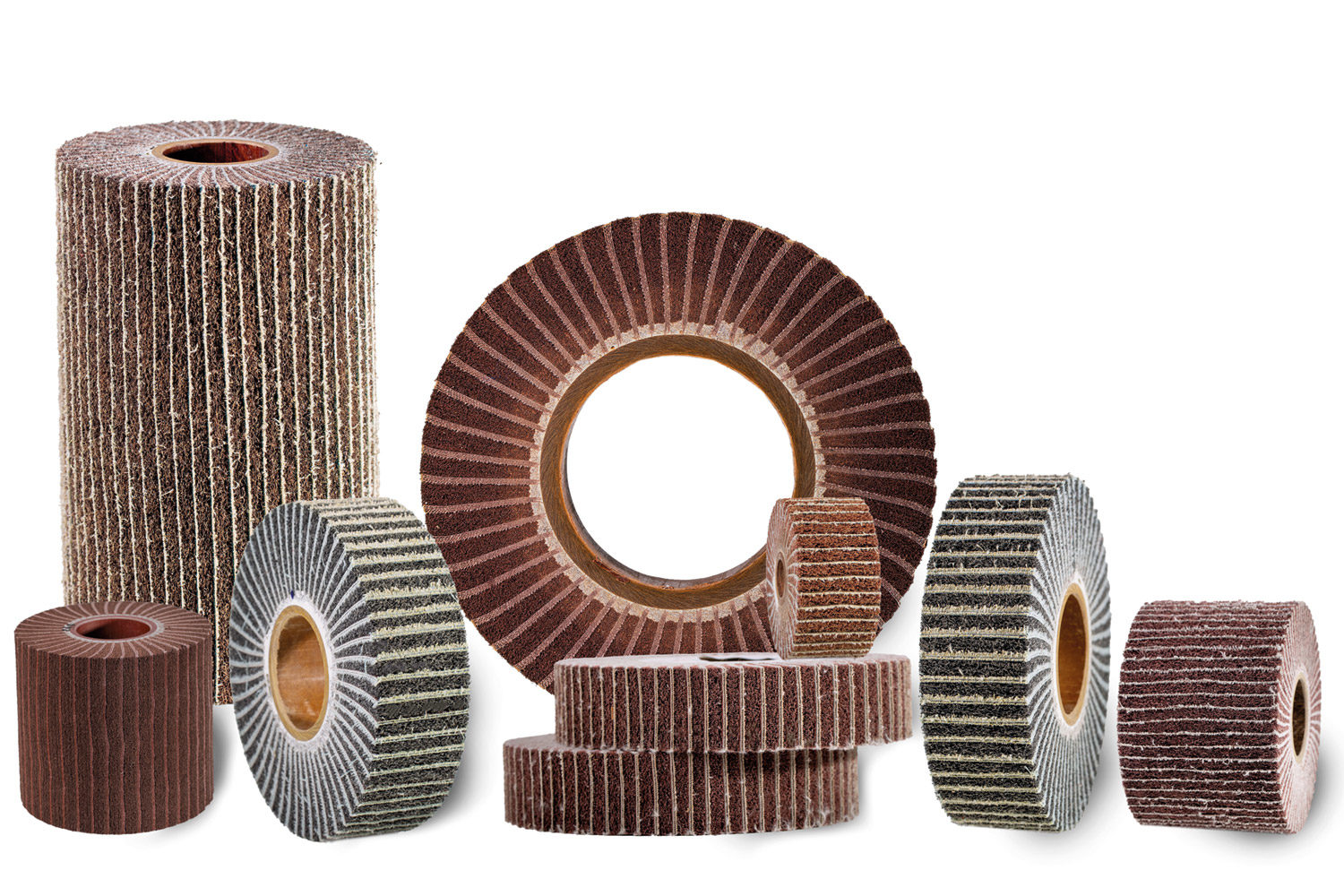

Mixed flap wheels

Mixed flap wheels are composed of TRINYL flaps alternated with abrasive paper, abrasive cloth or net flaps that are radially attached onto a fibre core. They are available in a large variety of combinations: all types of TRINYL may be combined with any abrasive grade and any backing available among the flexible abrasives. These combinations offer a vast range of flap wheels that allow them to be used on just about any type of job.

For more information regarding the characteristics of our TRINYL material, see general characteristics of TRINYL.

The ratio between the number of TRINYL flaps and the number of paper/cloth/net flaps is such as to assure the greatest efficiency.

Mixed paper flap wheels

They are composed of TRINYL flaps alternated with abrasive paper flaps radially glued on a fibre core. By varying the ratio between the flaps that make up the wheel, it is possible to obtain different degrees of removal in order to satisfy different working requirements. The mixed-paper flap wheels, appropriately shaped, are recommended for the treatment of primer paints on frames, sections, panels and in the furniture industry in general. Recommended peripheral speed: 15–30 m/sec. Depending on the type of work being done, the paper or cloth ratio to Trinyl can be varied.

Mixed cloth flap wheels

They are composed of TRINYL flaps alternated with abrasive cloth flaps radially glued on a fibre core. By varying the ratio between the flaps, it is possible to obtain many degrees of abrasion and finishing in order to satisfy different working requirements. Fitted on column buffing machines, portable tools or automatic pallet machines, the mixed-cloth flap wheels are recommended for polishing and satin-finishing of metals with a high degree of finish. Reduction flanges are available to adapt the wheels on shafts of different diameters. Recommended peripheral speed: 20–30 m/sec. Depending on the type of work being done, the paper or cloth ratio to Trinyl can be varied.

Mixed net flap wheels

They are composed of TRINYL flaps alternated with abrasive “NET” flaps radially glued on a fibre core. By varying the ratio between the flaps, it is possible to obtain many grades of finishing in order to satisfy the customer’s needs. Thanks to this particular combination between the Abrasive “NET” and Trinyl it is possible to work both on metal and on “soft” surfaces. The advantage is the possibility to have a wheel that is always sharp and cutting, that doesn’t clog and leaves the piece being worked on clean. An ideal product when you need to obtain premium satin-finishing.

The mixed net flap wheels are fitted on column buffers or automatic machines. Recommended speed: 20–30 m/sec.

Flap wheels reducing flanges

The flanges are made of aluminium, turned, centred and perfectly balanced making the job of changing the wheel fast and simple.

For more information, don't hesitate to contact our Customer Service department:

+39 0721 864864 | impex@awf-abrasives.com