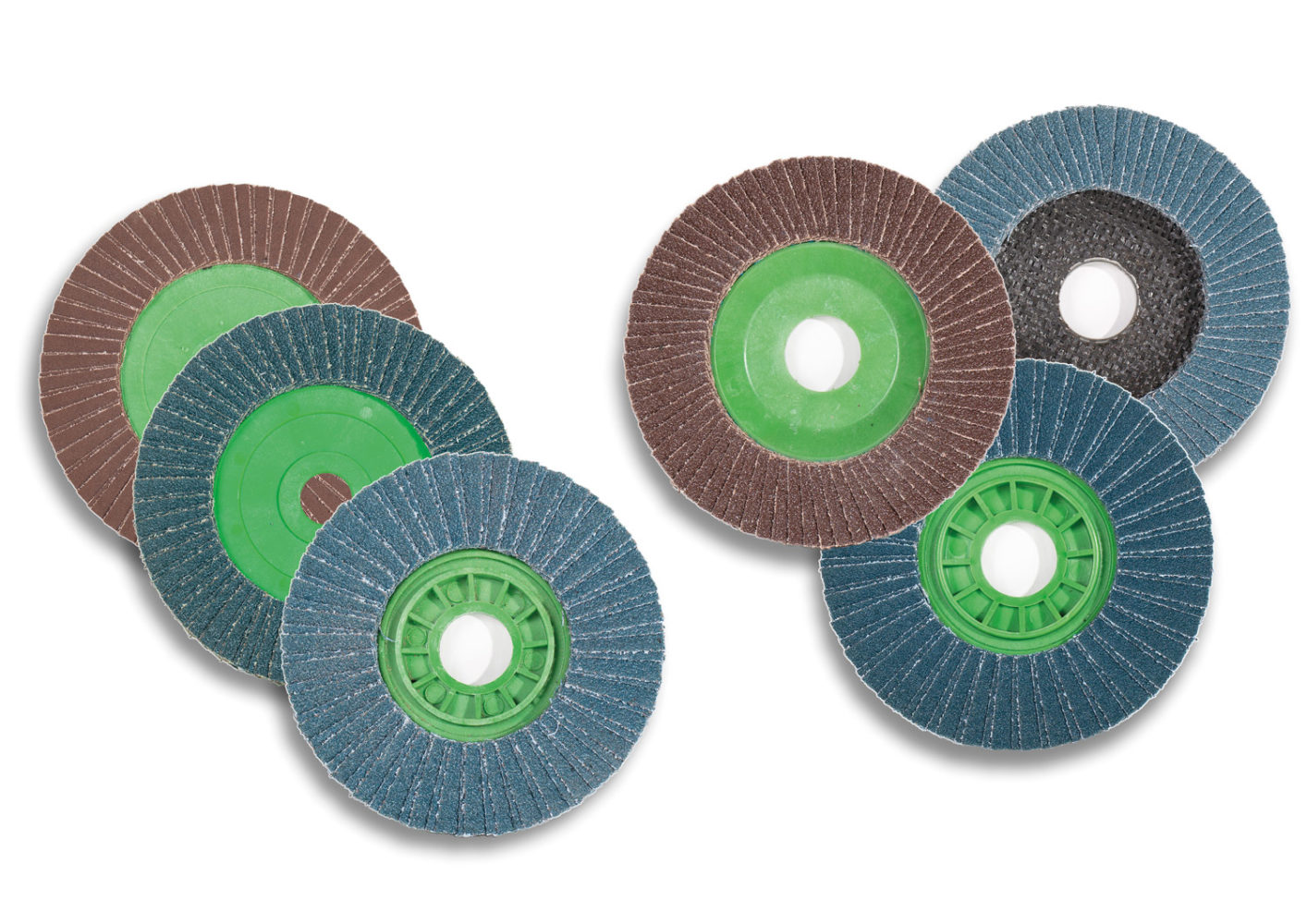

Flap discs

The flap discs are composed of overlapping abrasive cloth flaps and radially glued on backing made of plastic or high-strength fibreglass. They are used successfully for the removals of welding and imperfections and for removals on all types of materials (metal, wood, resins). They guarantee a high degree of removal and considerable durability due to their capacity for self-sharpening until the flaps are worn out.

The flap discs are meant to be fitted on angular polishing machines and are especially suited for removing welding beads, spots, recesses, bevels and carpentry work in general.

As far as monitoring during the various phases of production goes, the most important involves checking the maximum speed of rotation and bursting. Performance that meets sampling requirements guarantee the production of discs that are in compliance with international safety standards.

Professional disc

Of very strong construction on nylon plate and with a large quantity of cloth arranged in a double flap, they are created to achieve the highest quality levels in all carpentry applications: deburring, beveling, removing welding beads, deoxidizing, producing finishes on metal plate, on metals generally, steel, aluminium and alloys. The high abrasive capacity of the ZIRCONIUM cloth makes the disc ideal for more heavy-duty work, as on stainless steel. The version with ALUMINIUM OXIDE cloth is more suited for generic work.

Cost-effective disc

The “cost-effective” flap discs are produced using a thin plastic plate and, since it is slightly smaller compared to the professional one fitted singly, the flap makes this disc very versatile and lighter.

The version with ZIRCONIUM cloth is more suited for heavy-duty work and stainless steel, the ALUMINIUM OXIDE version is recommended for generic work.

Fibred cost-effective disc

The fibered “cost-effective” discs have the same specifications of the “cost-effective” discs, but with fibreglass backing. The cloth can be with ZIRCONIUM or ALUMINIUM OXIDE.

For more information, don't hesitate to contact our Customer Service department:

+39 0721 864864 | impex@awf-abrasives.com